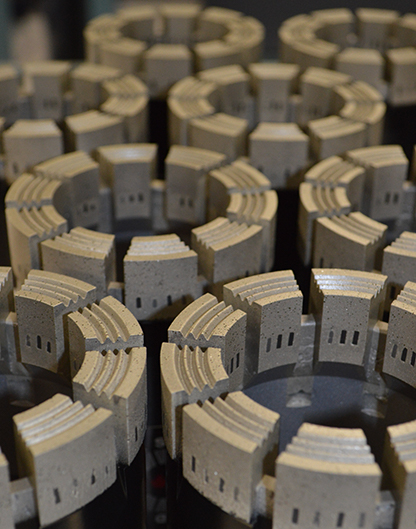

Mining Drill Bits

Innovative Diamond Core Drilling Tools for Maximum Efficiency

From the vast Canadian Shield to the resource-rich mining centers in the USA, Mexico, South America, Eastern Europe, South Africa, the Middle East, Central Asia, and Australia, drillers rely on our high-quality diamond tools to quickly reach the target depth.

Mining Drilling Fluids & Additives

- Bentonite Products - Mineral Exploration

- Cements & Grouts - Mineral Exploration

- General Chemicals - Mineral Exploration

- Greases, Lubricants & Compounds - Mineral Exploration

- Lost Circulation Materials - Mineral Exploration

- Mineral Processing - Flotation Products

- Polymer Additives - Mineral Exploration

- Specialty Products - Mineral Exploration

- Thinners/Dispersants - Mineral Exploration

- Waste Treatment - Mineral Exploration

- Weighting Materials - Mineral Exploration

Oilfield Drilling Fluids

- Alkalinity Controllers - Oil & Gas

- Bactericides - Oil & Gas

- Calcium Removers - Oil & Gas

- Corrosion Inhibitors - Oil & Gas

- Filtrate Reducers - Oil & Gas

- Flocculants - Oil & Gas

- Lost Circulation Materials - Oil & Gas

- Lubricants - Oil & Gas

- Oil and Gas Defoamers

- Polymer Breakers - Oil & Gas

- Shale Inhibitors - Oil & Gas

- Specialty Additives - Oil & Gas

- Surfactants - Oil & Gas

- Thinners/Dispersants - Oil & Gas

- Viscosifiers - Oil & Gas

- Weighting Materials - Oil & Gas

Trenchless, HDD, & Infrastructure Drilling Fluids & Additives

- Directional Drilling Fluids & Additives

-

Geothermal Drilling Fluid Additives

- Bentonite Products - Geothermal

- Cements & Grouts - Geothermal

- General Chemicals - Geothermal

- Greases, Lubricants & Compounds - Geothermal

- Lost Circulation Materials - Geothermal

- Polymer Additives - Geothermal

- Specialty Products - Geothermal

- Surfactants/Foam - Geothermal

- Thinners/Dispersants - Geothermal

- Weighting Materials - Geothermal

- Infrastructure Drilling Fluid Additives

-

Tunneling Drilling Fluid Additives

- Bentonite Products - Tunneling

- Flocculants & Coagulants - Tunneling

- General Chemicals - Tunneling

- Greases, Lubricants & Compounds - Tunneling

- Lost Circulation Materials - Tunneling

- Polymer Additives - Tunneling

- Specialty Products - Tunneling

- Surfactants/Foam - Tunneling

- Thinners/Dispersants - Tunneling

- Waste Treatment - Tunneling

Oilfield Cement Additives

- Accelerators

- Acidizing Specialty Additives

- Alkalinity Controllers

- Bactericides

- Buffers/pH Adjusters

- Calcium Removers

- Cement Foamers

- Corrosion Inhibitors

- Defoamers/Antifoamers

- Evaporate Stabilizers

- Extenders

- Lost Circulation Materials

- Oil Well Cement

- Retarders

- Shale Inhibitors/Clay Stabilizers

- Specialty Additives

- Thinners/Dispersants

- Viscosifiers

- Weighting Materials

Oil Sands Drilling Fluids, Additives, Consumables, and Accessories

- Accessories & Consumables

- Bentonite Products - Oil Sands Coring

- Cements & Grouts - Oil Sands Coring

- General Chemicals - Oil Sands Coring

- Greases, Lubricants & Compounds - Oil Sands Coring

- Lost Circulation Materials - Oil Sands Coring

- Polymer Additives - Oil Sands Coring

- Sand – Oil Sands Coring

- Specialty Products - Oil Sands Coring

- Thinners/Dispersants - Oil Sands Coring

- Weighting Materials - Oil Sands Coring

Tooling, Consumables and Accessories

Superior Quality Diamond Coring Tools for All Drilling Conditions

Drillers Edge mining diamond tooling from Di-Corp continues to evolve through rigorous testing and innovation. Our product line-up includes high-performance reaming shells, diamond drill bits, and rod and casing shoes for diamond core drilling. In 2022, Di-Corp improved its entire range of bit matrices to deliver enhanced performance across various rock formations.

- 21 CoreMatrix drill bit matrices featuring three unique waterway designs.

- Most diamond-impregnated drilling bits are available in “Abrasive” and “Endurance” formulations.

- Optimized for maximum penetration across all formations, from unconsolidated to consolidated rock (hardness groups 1–10).

- Reaming shells are offered in diamond-impregnated and surface-set options, covering all standard DCDMA sizes.

The Diamond Tool Essentials for Your Drilling Operation

Our extensive inventory of mining diamond tools includes products designed to increase drilling efficiency and withstand the challenges of high torque, rapid penetration, and heavy loads. Built for maximum durability, our selection of tools excel in the most demanding environments. Explore our range of diamond mining tools tailored explicitly for underground mining operations.

Casing Shoes

Ensure reliable performance, improve drilling efficiency, and prevent the casing from snagging on borehole irregularities with our high-quality casing shoes.

CoreMatrix® Diamond Impregnated Bits

Designed for durability, our diamond-impregnated bits penetrate various bedrock types, providing exceptional performance and enhanced cutting ability through diverse rock formations.

Reaming Shells

With EDGE reaming shells, you can achieve accurate hole diameters, prevent premature wear, minimize stuck tubes, and ensure stability.

Rod Shoes

Rod shoes are engineered with deeper impregnation depths, higher diamond concentration, and precise gauge settings to ensure the reliable seating of drill rods into bedrock. These features increase durability and provide consistent performance for demanding drilling applications.

What Our Customers Say About Our Efficient Drilling Diamond Tools

Our Di-Corp-manufactured bits perform as good or better than those from any other manufacturer under the most difficult conditions.

Mud Master Drilling Products, Kazakhstan and Uzbekistan

One of our key drilling customers has been regularly getting 33 percent more bit life with CoreMatrix bits by Di-Corp Drillers Edge.

Arson Mining Geotechnic Co. Ltd., Di-Corp distributor in Turkey

Why Choose Di-Corp

Di-Corp has garnered a reputation for being a leading manufacturer and distributor of specialized parts, chemicals, and accessories for the mining, drilling, and energy sectors. In addition to producing diamond core drilling tools, we manufacture and distribute a wide range of drilling fluids and additives, offering complete support for all drilling operations.

One-Stop-Shop

Warranty of Product

Customer Service

Frequently Asked Questions

How can I arrange for a trial of Drillers Edge mining bits?

We highly value feedback from field trials and look forward to working with you to test our bits. We’re happy to support a trial, provided our drilling specialist can collaborate with your operators onsite to ensure optimal conditions for the best performance. Please contact your Di-Corp representative to coordinate the details and arrange a trial.

What factors should be considered when selecting a diamond drill bit for mining?

When selecting the right diamond drill bit, it’s important to consider factors such as the rock formation type, material hardness (measured on a scale from 1-10), and the specific drilling environment (wet, dry, or abrasive). Other key considerations include bit longevity, penetration rate, and the need for straighter holes. Di-Corp’s diamond mining drill bits are designed to tackle a variety of rock types and are available in numerous formulations to ensure optimal performance for diverse drilling applications. Our drilling experts are ready to help you select the ideal bit for your project—reach out to our team through our contact page for personalized guidance.

What’s the difference between diamond-impregnated and surface-set bits?

Advancements in diamond core drilling have made diamond-impregnated bits the preferred choice in the mining industry. Unlike traditional surface-set bits, which feature a single diamond layer and wear out quickly in harsh conditions, impregnated bits are built with multiple diamond layers throughout the matrix, offering a longer lifespan.

How does Di-Corp ensure its products meet industry standards for drilling efficiency?

All mining diamond tooling products undergo rigorous testing to ensure they meet or exceed industry standards for efficiency and durability. Di-Corp’s design team is constantly improving the product lineup through innovation, ensuring tools such as our CoreMatrix mining drill bits perform well in a range of rock formations, from unconsolidated to consolidated rock.

What is the impact of diamond tool wear on drilling performance?

Diamond tool wear can significantly impact drilling performance by reducing penetration rates and increasing maintenance requirements. Di-Corp’s diamond bits are designed to minimize wear with tougher diamond layers and specialized matrices that help maintain performance over time. This design leads to more consistent performance and lower costs in mining operations.

What is the difference between 'Abrasive' and 'Endurance' diamond drill bit formulations?

Di-Corp offers most diamond-impregnated drill bits in two formulations:

- Abrasive – Designed for drilling in highly abrasive rock formations where rapid wear is a concern.

- Endurance – Built for extended bit life, offering durability in challenging drilling conditions while maintaining high penetration rates.

Why are reaming shells important in diamond core drilling?

Reaming shells help maintain borehole stability by ensuring an accurate hole diameter. They also minimize stuck tubes and premature wear on drill strings, making them an essential component of any efficient core drilling operation.

How do I request a quote for mining drill bits?

You can request a quote by visiting our product pages and clicking [Add to Quote] for the necessary tools. Alternatively, you can contact our customer service team for personalized assistance in selecting the best mining drill bits for your application.

How do casing shoes and rod shoes enhance drilling efficiency?

Casing shoes help guide the casing into the borehole and prevent it from snagging on irregularities, ensuring smooth casing placement and protecting it from damage. Rod shoes protect the drill rods, provide proper alignment, and help them seat securely in the bedrock. This ensures optimal performance by reducing wear on the rods and improving drilling efficiency.

- CONTACT US

Maximize Core Recovery With Di-Corp's Drillers Edge Diamond Tools

Di-Corp provides durable mining diamond tools such as coring bits, reaming shells, and shoes, engineered for quick penetration and smooth cutting in even the most challenging drilling conditions. Discover our selection of high-performance diamond tools and get a customized quote for your business today.

"*" indicates required fields